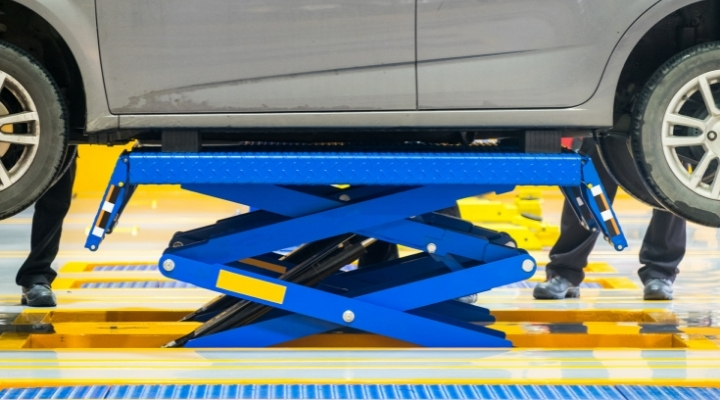

A scissor lift is a lifting equipment that allows you to conveniently work in the lower part of a vehicle. Less cumbersome and easy to use, it represents the best alternative to fill your garage equipment. From professional models to those designed for individuals, there is a wide variety of them on the market. To learn more, follow this guide.

Here is our commitment, to make sure that we provide the best user experience and content quality:

You can support us by using our links to make your purchases (at no extra cost to you)! This sometimes earns us a commission which allows us to remain independent. More about us

Our selection

"Ideal for simplifying the maintenance and repair of your vehicle, the MW-Tools MSL300M is a mobile scissor lift with a maximum lifting height of 98…"

"The Drakkar S15398 is a hydropneumatic scissor lift with a capacity of 680 kg and a lifting height of 830 mm. It has a 1950…"

"The MW Tools SL300UM features a dual scissor design with a synchronized dual cylinder hydraulic lift system. It has a load capacity of 3 tons…"

"With a lifting capacity of 2.5 tons, the Redats L-520 is a low lift mobile scissor lift with a maximum height of 620 mm, ideal…"

Ideal for simplifying the maintenance and repair of your vehicle, the MW-Tools MSL300M is a mobile scissor lift with a maximum lifting height of 98 cm and a capacity of 3 tons.

1 582 £ on ManomanoAdopting hydraulic lifting system, MW-Tools MSL300M is a low-lift mobile scissor lift with a capacity of 3 tons. This elevator has a maximum lifting height of 980mm with synchronous double cylinder design. For safe operation, it has a safety lock on the compressed air and also benefits from a safety valve against overloading the oil circuit.

Perfect for servicing and repairing your car, the MSL300M offers a better alternative even for small shops where fixed models cannot fit. Requiring a 220V power supply, the scissor lift comes with a pump and control console on wheels and a 5m power cable without plug. It also comes with adjustable rubber heads.

The Drakkar S15398 is a hydropneumatic scissor lift with a capacity of 680 kg and a lifting height of 830 mm. It has a 1950 x 964 mm platform and is supplied with a manual and pneumatic pump.

1 339 £ on ManomanoThe Drakkar S15398 is a stationary hydropneumatic scissor lift perfect for working on two and four-wheelers such as motorcycles, quads, riding lawnmowers and carts etc. In addition to its performance, this stationary scissor elevator model has a lifting capacity of 680 kg and a maximum lifting height of 830 mm

Its platform defines initial dimensions of 1950 of length and a width of 964 mm extensible via an extension of 254 mm. Supplied with a manual and pneumatic pump, this model of scissor lift adopts a mechanical locking security. With a 3-year warranty, it has a versatile aspect to perform maintenance and assembly work safely.

The MW Tools SL300UM features a dual scissor design with a synchronized dual cylinder hydraulic lift system. It has a load capacity of 3 tons with a maximum height of 1850 mm.

3 291 £ on ManomanoMW Tools SL300UM is a 3 ton scissor lift with a lifting height of 1850mm. It operates on 230 V electrical voltage and adopts a hydraulic lifting system with double synchronized cylinders. It is equipped with a double air lock and a safety valve to prevent overloading of the oil circuit for safer operation. It also has a manual lowering in case of electrical failure.

The structure of this elevator is based on a double scissor design and is designed for surface mounting. With a lifting and lowering time of about 55 seconds, it establishes a minimum height of 105 mm and has two synchronized platforms with dimensions of 1450 x 635 mm. The scissor lift requires 20 liters of oil and is supplied with an independent low-voltage control console as well as loading and unloading ramps.

With a lifting capacity of 2.5 tons, the Redats L-520 is a low lift mobile scissor lift with a maximum height of 620 mm, ideal for all types of vehicles.

1 832 £ on CdiscountAny specific needs?

The best entry-level scissor bridge

The best high-end scissor bridge

Your guide :

Rate this buying guide :By rating this buying guide, you are helping us to reward our best writers. Thank you!

| Best | Inexpensive | Top of the line | Excellent | |

In accordance with our commitment, this buying guide does not contain any sponsored products. |

8/10 |

7/10 |

9/10 |

8/10 |

| OUR SELECTION |

MW-Tools MSL300M

|

DRAKKAR Equipment S15398

|

MW-Tools SL300UM

|

Pont élévateur ciseaux PRO Redats L-520

|

|

Ideal for simplifying the maintenance and repair of your vehicle, the MW-Tools MSL300M is a mobile scissor lift with a maximum lifting height of 98 cm and a capacity of 3 tons.

|

The Drakkar S15398 is a hydropneumatic scissor lift with a capacity of 680 kg and a lifting height of 830 mm. It has a 1950 x 964 mm platform and is supplied with a manual and pneumatic pump.

|

The MW Tools SL300UM features a dual scissor design with a synchronized dual cylinder hydraulic lift system. It has a load capacity of 3 tons with a maximum height of 1850 mm.

|

With a lifting capacity of 2.5 tons, the Redats L-520 is a low lift mobile scissor lift with a maximum height of 620 mm, ideal for all types of vehicles.

|

|

|

Maximum load

|

3 tons

|

680 kg

|

3 tons

|

2.5 tons

|

|

Maximum lift height

|

980 mm

|

830 mm

|

1850 mm

|

620 mm

|

|

Minimum height

|

180 mm

|

185 mm

|

105 mm

|

100 mm

|

|

Mechanism

|

Hydraulic

|

Hydropneumatic

|

Hydraulic

|

Hydraulic

|

|

Dimensions

|

1600 x 1500 mm

|

1950 x 964 mm

|

1450 x 2045 mm

|

1400 x 1880 mm

|

Help us improve this table:

Report an error, request the addition of a feature to the table, or suggest another product. Thank you for your kindness!

We spend thousands of hours each year studying the major specialized websites, analyzing products of hundreds of brands and reading user feedback to advise you on the best products.

We are a product review company with a single mission: to simplify your buying decisions. Our research and testing helps millions of people every year find the best products for their personal needs and budget.

To support us you can: use our links to make your purchases (which often earns us a small commission), share our articles on social networks, or recommend our site on your blog. Thanks in advance for your support!

When it comes to choosing a scissor lift, it is mostly going to be about lifting a certain load. So, it would be convenient to consider the maximum load capacity that the lift can lift and support. But this will also depend on the type of use and the weight of the vehicle or what you plan to lift with the equipment. The majority of scissor lifts on the market will have load capacities ranging from 350 to 3500 kg depending on the model. Those with a low load capacity will be mostly dedicated to lifting light two and four wheelers such as motorcycles, quads, buggies or riding lawnmowers and the like. For heavier vehicles, there is a variety with a load capacity of over 2 tons, from passenger cars to vans.

The maximum lifting height is a determining feature to adapt to the type of indoor or outdoor installation of the scissor lift. At this level, the choice will be much more oriented according to the interventions you plan to make using your lift. On the market, there are models with a lifting height ranging from 500 to 2000 mm and even more. Indeed, for an easy access under hull, it would be advisable to focus on a model with a lifting height from 150 mm to 2000 mm or more. This will simplify complete underbody interventions such as certain repairs and adjustments of wheels, gearboxes, transmissions and so on. For simple maintenance activities such as vulcanization or body repair, a lift height ranging from 100 to 120 mm will be sufficient and adequate for ordinary intervention activities.

In general, scissor lifts use a hydraulic lift system that comes in two types of drive including electrohydraulic and hydropneumatic. The first type uses an electric motor to engage the hydraulic system of the scissor lift for total control of the lifting and lowering. This one is mostly equipped with a control panel to access the different functions of the lift. As for the second model, this compressed air powered drive system includes a connection to a compressor or a pneumatic pump for lifting. Lowering is done via a crank or pedal placed on the base of the scissor lift or separately. It should be noted that the electro-hydraulic model represents a much more ergonomic and efficient aspect in terms of load capacity and lifting height. The hydropneumatic drive system is mainly oriented for low lift types of scissor lifts and with a rather limited load capacity.

This criterion is especially important to guarantee a safer use during an intervention at height so that the lift avoids giving way. Thus despite the power of the hydraulic cylinders of the scissor lift, it is crucial to check the safety devices with a blocking or locking system as well as unlocking. It is also advisable to choose a model with mechanical safety catches. This system will be essential to mechanically stop the scissor lift in case of hydraulic leakage.

Scissor lifts also differ in their installation base including the free-standing, flush-mounted or even mobile types. To better choose the right model for your shop, it is important to focus on this type of feature to ensure a compliant installation. However, it is important to point out that mobile or free-standing models require a floor slab with a minimum thickness of 150 mm. And regarding the models to be embedded, it will require a slab with a reservation designed specifically for this purpose. As a general rule, it requires a masonry intervention for an adapted and optimal installation.

Due to their design and structure, scissor lifts are easily moved and allow you to raise your work surface to an adequate height for your interventions. However, it is necessary to take certain steps to ensure safe and efficient lifting. In principle, to use a scissor lift, it is strongly recommended to respect the load capacity of your equipment. Before use, it is advisable to check the stability of the lift on the ground. To assemble the vehicle, try to position it according to its center of gravity while placing it in the right direction in relation to the scissor lift. After these different steps, you will just have to find the lifting points by installing rubber pads dedicated to this purpose in order to ensure great stability to the lifting.

For more safety, it is preferable to ensure the stability of the vehicle on the platform by lifting it to a height of about 300 to 400 mm. Then check by pushing sideways and back and forth on the sides. In case of instability, you will have to lower the bridge and reposition the vehicle and repeat the previous steps. If not, you could continue the lifting process until you reach the right height to tackle the different interventions on your vehicle.

But be careful when lifting, it is not to be neglected to watch the engagement of the safety devices such as the locking latches to avoid the risks of hazard like a sudden descent or others.

The simple scissor lift or low lift scissor lift defines a structure identified with a lifting table with a lifting height ranging from 500 mm to 110 mm and a capacity up to 3000 kg depending on the model. It is mainly designed for pneumatic and bodywork interventions. With a space-saving appearance and a folded height of about 10 cm, it is also recommended for workshops with low ceiling height. Its design allows working on the front and rear axles of the vehicle, but will be constrained on the central part. This type of scissor lift can be installed without using fixed components. Some models can also be mobile so that they can be moved as needed. Others can also be recessed into the ground so that they fold into the ground and do not protrude when folded.

In addition to its advantages, the single scissor lift benefits from a compact but efficient structure and with a price that is more accessible than other elevator models.

Posed or embedded in the ground, the double scissor lift stands out with a lifting system consisting of two synchronized lateral platforms while allowing an intervention under the entire length of the vehicle. This type of scissor lift has the advantage of supporting higher loads up to 5000 kg with a lifting height from 120 to 2000 mm or even more depending on the model. At rest, it has the same advantages as the simple scissor lift with a minimum height of about 100 to 150 mm to be easily stored under the vehicle.

Its main advantages lie in its capacity to handle heavier loads with a lifting height of man's length and even more. It also allows underbody intervention from the undercarriages to the exhaust through the center part of the car.

Determining the same principles of a double scissor lift, the geometry scissor lift defines larger dimensions for an underwheel pickup. It differs with longer ramps for an under-wheel pickup and equipped themselves with secondary platforms serving as auxiliary lifts. These are used for undercarriage pick-up with an additional lifting height of up to approx. 500 mm. The main ramps are equipped with swivel platforms for alignment work and geometry checks. This type of scissor lift is especially suitable for professionals and garages looking for an elevator with full underbody access.

The geometry scissor lift is mainly designed for various technical controls, geometry, repair and several adjustments on the lower part of a car. It also features anti-skid plates for wheels and adopts technology to generate a manual posture for the user.

Its only disadvantage is that it is a little more expensive to buy and install, and its structure is less compact than the two previous models.

Scissor lifts are characterized by a design of the lifting system defining an accordion mechanism. They rise to the top and fold to the ground by means of a hydraulic system with scissor-shaped support centers. They are available in different ranges of heights and load capacities according to the models designed for each type of workshop. They are also available in different lifting capacities, some of which are chassis or underbody lifts and others are under wheel lifts. Low height scissor lifts will lift up to 900 mm from the ground, medium height scissor lifts will determine a lifting height between 900 and 1200 mm and maximum height scissor lifts can go up to 2000 mm and even more.

To its advantage, they represent the best alternative when it is a question of having a clear ground surface, without posts or other restrictions in the space when the bridge is no longer used. They also have the advantage of offering a fast, simple and safe loading of the vehicle.

On the other hand, some scissor lifts have the disadvantage of being limited in terms of accessibility to the central part of the vehicle. They only allow work on the front and rear parts of the vehicle, such as on the wheels and axles, or to change the engine oil, for example.

A 2-post lift is a lifting system consisting of a pair of posts called posts equipped with lifting arms and placed face to face on opposite sides. It varies according to its lifting design, either auger or hydraulic, asymmetrical or symmetrical. The hydraulic lifting system is the most common and evokes a much more solid appearance. The two-post lift is characterized by an underbody lifting system with supports placed on each side of the vehicle leaving the wheels hanging.

The advantage of this system is that it allows free and unobstructed access to all the lower parts of the car. Moreover, it does not require much floor space for installation. But on the other hand, it has the defect of requiring a height under ceiling quite consequent with the vertical length of its columns. Also, for an optimal installation and to facilitate heavy loads, the two-column bridge must have a very solid anchoring to the ground in order to guarantee a great safety in use.

Indeed, each of these elevators has its own advantages and disadvantages that need to be analyzed in order to better orient yourself in your needs. A scissor lift is the best option if you have limited space for installation. For unobstructed access under the body, a two-post lift is an excellent option, but with a much more complex floor installation and considerable headroom.

The use of a scissor lift can bring several advantages, whether in terms of productivity and efficiency or in terms of simplicity and practicality. Varying in load capacities and lifting heights, scissor lifts have many common advantages.

Mobility and compactness

In fact, the vast majority of scissor lifts are designed for low ceilings and can be installed in private garages and do not need to be bolted or anchored into a floor slab. This is an important advantage for users who often want to move their elevator, such as tenants and those who do not want to interfere with the masonry of their floor. Moreover, when not in use, they retract to the floor and adopt bases without fixed components in order to benefit from mobile faculty to be moved according to the activity in the workshop.

Ergonomics

The main advantage of scissor lifts is that they offer better ergonomics to facilitate quick and easy intervention. Due to its structure and design, it allows for a clear and uncluttered area around the vehicle and even when opening the doors. Indeed, using a scissor lift will give you a better access to the different components of the vehicle while optimizing different repair, adjustment or maintenance interventions on the lower area.

Lifting speed

Having a hydraulic drive system, the scissor lifts have for strong point the lifting speed. They have a lifting speed performance of 25 to 30 seconds on a height of more than 100 mm with a great stability.

The simplicity of use

Practical and efficient, a scissor lift is also very easy to use. Simply position the vehicle over the platform and then lift it to the proper lifting height. Unlike some models of elevators, a scissor lift does not require the installation of arms or other fasteners before the lifting process.

Safety in use

Scissor lifts are very reliable equipment due to their advanced safety features. They are equipped with a safety device with a secure locking and unlocking system to avoid any risk of danger in case of accidents during its use.

In our opinion, the best brands of scissor bridges in 2022 are :

Subsidiary of the Italian group " Metal Works " founded in 1967, MW was established in the UK in 1987. MW - Tools is a brand specialized in tools, equipment and workshop fittings. Offering a wide range of products, it distinguishes itself by a very competitive quality-price ratio on the market. Concerning its scissor lifts, they are well known for their high quality hydraulic and compressed air systems. For its products, the brand commits to a minimum warranty of 2 years while offering thereafter a perennial follow-up of spare parts.

Originally Polish, the Redats brand takes its draft around the year 2006 under the name PHU Szczepan to adopt its current name in 2017. Its activities are oriented in the production of essential items for any automotive repair and tire service. The most popular items in its catalog are the range of tire changers, balancers, compressors as well as the category of elevators. With a motto of impeccable quality, its products are manufactured according to the strictest standards while applying rigorous quality control at each stage of production. Designed for both professionals and individuals, Redats scissor lifts are characterized by attractive prices while determining excellent quality.

Founded in 1997, Twinbusch is a brand specialized in garage equipment including elevators. It is distinguished by high quality products with excellent value for money. Present in the UK since 2009, the quality and performance of its elevators including scissor lifts have given it an unshakeable reputation while becoming one of the best references in garage equipment. Offering technical and specific products, the brand has won the trust of garages, enthusiasts' clubs and individuals with price ranges accessible to all. Apart from France and Germany, Twinbusch has several subsidiaries in several countries such as England, United States, Spain, Romania and the Netherlands.

Founded in 1970, Werther is an Italian brand that has been working for more than 40 years in the automotive service equipment and air compressor sector. Specializing in automotive lifting solution, the brand is highly regarded for its reliability and manufacturing quality of its products. Its products are available in a wide range of elevators such as 2-post and 4-post lifts as well as scissor lifts of all kinds. Among its best-known garage equipment, there are also tire changers, compressors, wheel balancers and air-conditioning charging stations, etc.

Provac is a French brand founded in 1978 and specializes in the pneumatic service sector. It is especially ranked as the French leader in active automotive safety. Its activities focus on the manufacture of equipment, accessories and tools for garages. Its ambition is defined by a guarantee of durability and technological advance to impose itself on the European market. Designing and developing a complete range of elevators including scissor lifts, Provac offers various equipment for assembly, tightening-inflation, balancing, alignment, repair, compressed air and mechanical. However, its products represent mostly high-end solutions designed for professionals.

The diagram below will help you to get an idea of the typical prices for each price range (entry-level, mid-range and high-end).

However, more expensive does not necessarily mean better.

We therefore advise you to always consult our ranking before deciding, rather than blindly relying on price ranges.

Maintain your scissor lift to maximize its lifespan

Maintaining the efficiency and reliability of your scissor lift will require regular and proper maintenance. Even if you are not highly skilled in this area, some basic maintenance and upkeep will be in order.

Indeed, after each use, it is advisable to check the condition of the lifting locks and safety devices. The same goes for the other elements and lifting parts while checking their functionality. At this level, it will be a question of the platform, the lifting shoes as well as the base and the lifting supports. You will also have to check the hydraulic system for leaks such as cylinders, lines and valves. You will also inspect the operation of various lifting and lowering controls.

And finally, you will have to make sure that it is clean and free of any type of dirt that could interfere with the proper functioning of your scissor lift. After these daily checks, it will be essential to lubricate the pulleys and drive rollers at least once every three months to maintain optimal performance of the mechanical elements. Finally, it is advisable to check the hydraulic oil level at least once a year and add more oil if it is low. Some manufacturers suggest changing the hydraulic oil while changing or cleaning the oil filter.

Choose a flat, solid surface to accommodate a free-standing or mobile scissor lift

Designed to lift a heavy load, the installation of a scissor lift on the ground must meet a certain standard. To do so, your shop will need to have a B20 or B25 floor slab class. For scissor lifts with a capacity of up to 3500 tons, the floor slab must have a thickness of 150 to 200 mm. At more than 200 mm thickness, the floor slab of your workshop will be able to accommodate a crane with a load of more than 4000 kg.

Thus to ensure the depth of the concrete slab, it will be necessary to use a perforator in order to measure it and to guarantee the robustness of the ground supporting your scissor lift.

Change your scissor lift's oil regularly

A scissor lift works like any mechanical equipment that requires regular maintenance such as lubricating oil renewal. In general, this will depend on how often the equipment is used. For frequent use, it is suggested to change the oil every 3 months. For occasional use, the oil should be changed at least every 12 months. Changing the oil in a scissor lift is a simple and easy process. In fact, to do so, simply empty the oil tank while closing the drain plug.

Afterwards, the tank must be refilled with new oil. Finally, restart the operation of the scissor lift by running up and down 3 to 4 times, leaving the tank cap open to drain the new oil from the lift. After these different steps, you could recork the tank and put back in service your lifting equipment.

Don't neglect the space needed for a scissor lift installation

In principle the space required for the installation of a scissor lift will depend on the model. It will be essential to consider the dimensions of the equipment both horizontally and vertically. It will also be crucial to consider the lifting height plus the height of the type of vehicle that will be lifted. In any case, to be able to circulate in your workshop with your elevator, it is suggested to have a space of at least 120 mm in addition to the dimensions of the equipment.

As for the ceiling height, it is recommended to have a height of 3 to 5 meters depending on the lifting height of the lift.

Don't hesitate to change a worn out hydraulic cylinder or ram on a scissor lift if necessary

It may happen that the hydraulic cylinder(s) of your scissor lift deteriorate over time. If you want to change it yourself, there is a very simple way to replace it. First of all, you need to find an identical or suitable cylinder or jack for the occasion. To do this, you will need to raise the deck to a certain height and then place some shims or a pallet under the platform. In order to start the process, the deck must be lowered until the platform rests securely on the chocks or pallet.

To tackle the actual part, remove the hydraulic hose and the compressed air hose. You can then unbolt the top and bottom of the cylinder by first removing the protective rings. Once unbolted, try to carefully remove the bolts so you can remove the cylinder. You can then proceed to install the new cylinder by reinstalling the bolts and the hydraulic and compressed air hoses. To finish your maintenance, it is advisable to check the oil level by adding it and to carry out a procedure of purging of oil for the good performance of your scissor lift.

An outdoor installation could have effects on the life span against the weather unlike an indoor installation. The scissor lift will rust much faster with different alterations of the different devices of the equipment. It should also be noted that most manufacturers will not accept any warranty in case of malfunction and deterioration due to any outdoor use.

Hydraulic oil determines a non-negligible element for an optimal function of the scissor lift. It will ensure the lubrication of the cylinders and piston rods of the lifting equipment. A low oil level can restrict the scissor lift in its maximum cleaning capacity. Dirty and very thick oil can also slow down the lifting and lowering of the crane. Therecommended oil for the hydraulic system will define a fluidity index ranging from 20 to 46. However, for scissor lifts, the use of oil that is too fluid in hot weather is not recommended by manufacturers and specialists in the field. It may cause some micro-leakage while the seals are not under pressure. The most common oils used for scissor lifts are HYD 20, HLP 32, HVI32, G32, HLP 46 or HV 46. For information, the most suitable in low temperature areas are hydraulic oils with flow index 32. As for temperate areas, hydraulic oil with index 46 would be suitable.

Generally these types of phenomena occur when air particles enter the hydraulic system hindering the proper circulation of hydraulic oil. This can also cause damage to other components and lead to oil degradation. This is why it is necessary to bleed the oil when filling the tank. In most cases, to remedy this, it will be necessary to drain the oil to eliminate the air and restore proper operation of the scissor lift.

Every month we help more than 1 000 000 people buy better and smarter.

Copyright © 2022 - Made with ♥ by buyingbetter.co.uk

Your reviews and buying guides 0% advertising, 100% independent!