The label is an important part of the product packaging. The label contains information about the product (origin, manufacturer's name, price, etc.). People also like to label their belongings and many other things for organizational purposes. But for all these jobs, you need a labeling machine. Just in time, our guide offers the best models of the moment.

Here is our commitment, to make sure that we provide the best user experience and content quality:

You can support us by using our links to make your purchases (at no extra cost to you)! This sometimes earns us a commission which allows us to remain independent. More about us

Our selection

"The Dymo LabelWriter 450 offers more than acceptable speed and can print on a wide variety of labels, including postal labels. It has an excellent…"

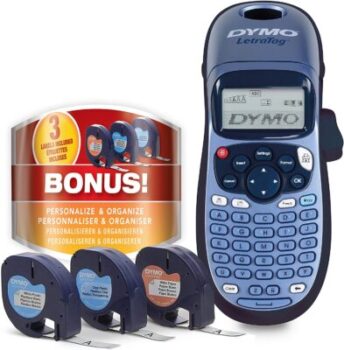

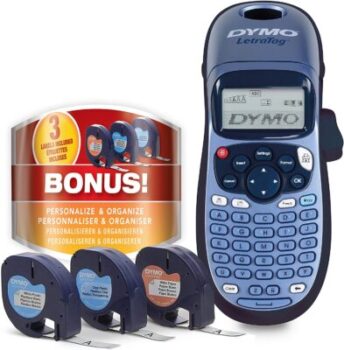

"The Dymo LetraTag 100H portable labeler is an inexpensive model. It can print labels on paper, plastic, iron-on fabric or even metal tape. This ultra-compact…"

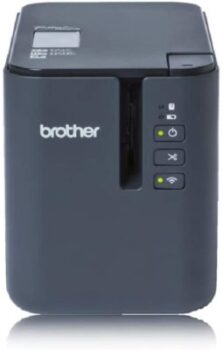

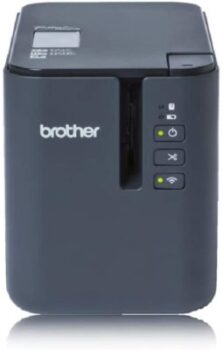

"With the Brother PT-P900W, you'll be able to create personalized, durable labels with a variety of color and width combinations. Although expensive, this device works…"

"The Dymo LabelManager 160 prints durable, water-resistant labels, making it easy to manage files and tools. Its main strengths are its rechargeable Li-Ion battery and…"

The Dymo LabelWriter 450 offers more than acceptable speed and can print on a wide variety of labels, including postal labels. It has an excellent print program as well as extensions for Word and Excel.

See priceA cousin of the LabelWriter 450 Twin Turbo, the Dymo LabelWriter 450 has a more classic design and a lower price. Unlike the Twin Turbo, this model can only hold one label roll at a time. And unlike the more expensive models, it lacks an automatic cutter. However, the label roll is easily torn by hand.

The advantage of this model is that it offers a wide selection of labels for the LabelWriter 450, with about 60 choices that vary in size, thickness and color. The configuration of this labeler remains standard despite the USB port. By the way, Dymo's label printing software is among the most comprehensive and easy-to-use labeling programs available today.

The Dymo LetraTag 100H portable labeler is an inexpensive model. It can print labels on paper, plastic, iron-on fabric or even metal tape. This ultra-compact labeler is very easy to use.

See priceThe Dymo LetraTag LT-100H has the size and shape of a small shoe. Note the compact dimensions and the rounded front and back. The height varies from about 25 mm at the front, which is the lowest point of the slightly sloping keyboard, to 66 mm at the top of the 13-character LCD. There are several buttons, including a Print button, between the top of the keyboard and the base of the LCD that allow you to use the built-in menus and issue commands.

The LCD screen is mounted at an angle for easy viewing, whether the printer is sitting on a desk or in your hand. Good to know, this model runs on 4 AA batteries, offers 5 different font styles and two-line printing. Dymo advertises a print speed of 12.7 mm/s. If you only print a dozen labels, this speed is quite acceptable. However, if you are creating more labels, it will seem slow.

With the Brother PT-P900W, you'll be able to create personalized, durable labels with a variety of color and width combinations. Although expensive, this device works fast and is feature rich.

See priceThe Brother PT-P900W offers a complete on-demand label printing solution. This labeler offers both wired and wireless connectivity. With a small footprint, it produces large, high-quality laminated labels at 360 dpi print resolution, up to 32 mm print height on a 36 mm ribbon, and has a built-in automatic paper cutter that cuts a continuous ribbon to virtually any length.

Performance-wise, the Brother PT-P900W does very well. The print speed is 60 mm/s. You're going to be able to instantly create and print labels from your smartphone or tablet without touching your PC, but simply through the Brother iPrint & Label app available on iOS and Android.

The Dymo LabelManager 160 prints durable, water-resistant labels, making it easy to manage files and tools. Its main strengths are its rechargeable Li-Ion battery and the ability to print from a computer or on the device.

See priceWith 6 font sizes, 8 text styles and over 200 symbols to choose from, the Dymo LabelManager 160 makes it easy to create high-quality labels for any need. Plus, it's compact and lightweight, making it easy to carry around and label just about anything, anywhere. This model is powered by 6 AAA batteries included.

The Dymo LabelManager 160 has a QWERTY keyboard for input and editing. It also features a one-touch formatting function for professional-level labeling. The 180 DPI resolution is still low, but for basic labels, it will suffice. The speed of 12 mm/s is also low, which is not suitable for large volumes of labels to be produced.

Any specific needs?

Your guide :

Rate this buying guide :By rating this buying guide, you are helping us to reward our best writers. Thank you!

| TOP OF THE LINE | CHEAP | TOP OF THE LINE | ALTERNATIVE | |

In accordance with our commitment, this buying guide does not contain any sponsored products. |

8/10 |

7/10 |

8/10 |

8/10 |

| OUR SELECTION |

Dymo LabelWriter 450

|

Dymo LetraTag LT-100H

|

Brother PT-P900W

|

Étiqueteuse – Dymo LabelManager 160

|

|

The Dymo LabelWriter 450 offers more than acceptable speed and can print on a wide variety of labels, including postal labels. It has an excellent print program as well as extensions for Word and Excel.

|

The Dymo LetraTag 100H portable labeler is an inexpensive model. It can print labels on paper, plastic, iron-on fabric or even metal tape. This ultra-compact labeler is very easy to use.

|

With the Brother PT-P900W, you'll be able to create personalized, durable labels with a variety of color and width combinations. Although expensive, this device works fast and is feature rich.

|

The Dymo LabelManager 160 prints durable, water-resistant labels, making it easy to manage files and tools. Its main strengths are its rechargeable Li-Ion battery and the ability to print from a computer or on the device.

|

|

|

|

Speed of 51 mm/s

|

Easy to use

|

USB and Wi-Fi connectivity

|

High responsiveness

|

|

|

Resolution of 300 dpi

|

Very lightweight

|

Rechargeable Li-Ion battery

|

Six AAA batteries for long battery life

|

|

|

More than 60 styles and layouts available on the companion software

|

Can print on metal tape

|

32mm print height

|

QWERTY keyboard

|

Help us improve this table:

Report an error, request the addition of a feature to the table, or suggest another product. Thank you for your kindness!

We spend thousands of hours each year studying the major specialized websites, analyzing products of hundreds of brands and reading user feedback to advise you on the best products.

We are a product review company with a single mission: to simplify your buying decisions. Our research and testing helps millions of people every year find the best products for their personal needs and budget.

To support us you can: use our links to make your purchases (which often earns us a small commission), share our articles on social networks, or recommend our site on your blog. Thanks in advance for your support!

If you know the maximum label width you need, choose a labeler that can print that size. For example, the most popular labelers print labels up to 104 mm wide. Printing technology plays an important role in the life of the label. Whether it's direct thermal or thermal transfer printing, each technology has its advantages and disadvantages, including how long the label will last in the face of particular weather conditions or temperature extremes.

The resolution of a label maker is measured in DPI (dots per inch). If you are printing labels for a product, your label will have a barcode on it, and the barcodes must be clear to be scanned and read by barcode scanners. Traditional label printers with 200 dpi are sufficient for text, numbers, barcodes and low resolution images. Printers that have a high resolution of 300 dpi or 600 dpi allow more information to be packed into a limited label space and improve barcode scanning capability. It is also the best way to produce 2D barcodes.

The size of the labeler (mobile, desktop, industrial) depends on the volume of printing done per day and whether the printer needs to be portable. Some labelers are designed to handle a large volume of labels, while others are better suited for small runs. When it comes to larger volumes, print speed is important, as you will lose productivity if the labeler can't keep up with a higher volume.

Some

people tend to go with the first printer that fits their budget. In the long run, however, this could cost more. It is important to keep in mind that not only is the initial cost of a printer important, but also the annual cost of replacing ink cartridges, ribbons and regular maintenance, etc. Another important thing to keep in mind regarding overall cost is ease of use. You should choose a printer that is simple and easy to maintain, but also user-friendly and simple to operate at the risk of spending extra time and money on staff training.

If you're connecting the labeler to a PC, USB is the most popular connection. If you need a model that allows multiple users to connect at the same time, you favor labelers that offer Ethernet (LAN) connectivity. If you carry the printer around and therefore want it to be portable, the printer should be able to pair with a PC or mobile device such as a smartphone or tablet via Bluetooth or Wi-Fi.

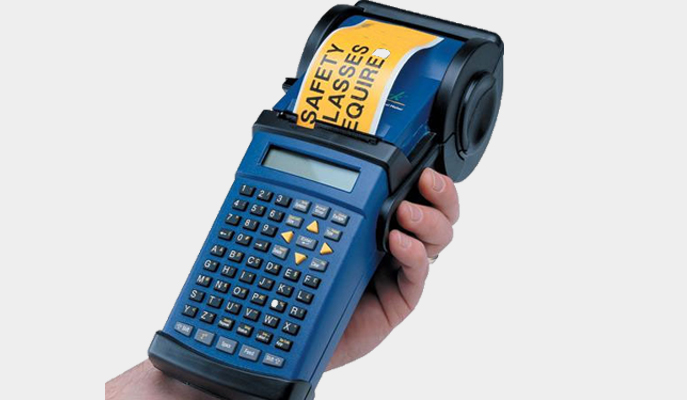

Simply put, a labeler is a printer used to produce labels on small self-adhesive papers or card stock. A labeler usually has a built-in keyboard and screen, which makes it stand-alone; that is, you don't need to connect it to a computer. Unlike stand-alone labelers, there are also models that need to be connected to a computer to operate.

Labellers are very different from regular printers in many ways. But we don't need to go into detail. These simple portable devices are useful when creating simple labels for the office and home. With the help of these compact devices, you can easily create labels whenever and wherever you want. Most labelers use a wide variety of labeling tapes made of paper, polymer and synthetic materials.

And when it comes to label maker connectivity, the best label makers include Ethernet, USB, Bluetooth and Wi-Fi. Although labelers are primarily used to label products, they can also be used for many other purposes. For example, you can make labels for your photo albums, cups, or for all kinds of storage accessories.

However, you have to be creative enough to find a relevant use. You can also use labelers in your office to organize your tasks such as labeling your briefcases with a list of dates, contents and other relevant data.

Labellers can be distinguished from each other according to their intended use. For example, there are office labelers, commercial and industrial labelers, and portable labelers. Let's take a look at all of these in detail.

Desktop labelers are fairly inexpensive, as they are generally designed and intended for light to medium use and will support label rolls of about 100 mm wide. They are primarily used in medium volume healthcare and commercial environments. They provide fast print speeds with a variety of useful additional features.

Lesktop labelers are generally recommended for high-resolution label printing, receipt printing, light manufacturing and retail labeling. These labelers are an ideal choice for an office environment.

Commercial labelers are designed for slightly heavier duty than office labelers and can use rolls up to 200 mm wide. These types of labelers are primarily used in MSEs and IPOs in manufacturing, packaging, retail and logistics. They are also a very good choice for small stores.

By

its title, it is pretty much obvious that this type of labeling machine is used in high demand industries such as asset management, inventory management and docking station management. Industrial labelers are specifically designed to handle the toughest environments, including factories, where there is a need to print labels continuously. The speed of these labelers can range from 4 to 8 fps.

As

the name suggests, these labelers can be easily transported without any difficulty. A portable labeler ranges from light to heavy industrial use, which means it can be used in both offices and factories. There are also domestic portable labelers for personal use at home or at school. These are models that have a fairly good resolution, but are not designed for continuous, heavy use.

A direct thermal labeler uses a thermal print head to heat chemically treated and heat activated labels. The labels pass through the printer and the print head heats the label surface. Printing is created when the label reacts by darkening in response to the heat from the printer.

This type of printing method is more cost effective because it does not require ink or ribbon and the labeler is generally more compact than a thermal transfer printer. The direct thermal printing method is ideal for shorter life labels such as shipping and delivery labels and food labelling. It is also ideal for printing receipts in small businesses, as it does not require a long shelf life. Most mobile labellers use direct thermal technology.

The main disadvantage of using direct thermal printers is that the printed image fades over time and is sensitive to exposure to heat and ultraviolet light. As a general rule, direct thermal labels have a shelf life of between 6 and 9 months, depending on the environment and the type of label used.

Thermal transfer printers use heat to bond or transfer a thin film of wax or resin in a carbon-based printer ribbon to a label. The ink is absorbed into the label creating a durable image. The print quality is higher and sharper than labels printed with direct thermal technology, making it ideal for printing barcodes and high density labels that require a longer life.

Thermal transfer printers can handle a wider variety of substrates; including paper substrates, polyester and polypropylene and even plastic film. Thermal transfer ribbons are available in a variety of colors, so printing is not limited to black. This type of printing method is recommended for labels that need to have a shelf life of more than 6 months, such as product identification labels, inventory labels, asset labelling, certification labels, interior and exterior signage, high density barcode labels, etc.

But the main disadvantage of using thermal transfer technology is that it is more expensive and the ribbons need to be replaced regularly. Also, it should be noted that when using a thermal transfer labeler, the label material and print ribbon must be carefully matched to maximize the quality and durability of the label, but also the overall performance of the device.

In short, the main difference between a thermal transfer labeler and a direct thermal labeler is that the former requires ribbons and the latter does not. Thermal transfer involves the printheads heating the back of a ribbon to melt and transfer the compounds into the label to create the image. Direct thermal printers use a heat sensitive label and the print head heats the media directly, causing the material to change color and create the image.

Many businesses find that they need both types of labelers to run their business effectively. So your choice will depend mostly on your specific needs and industry.

Consider the number of lines

If you intend to use your labeler to print address labels, you will need a labeler that can print multiple lines. Be sure to check the product description and specifications to ensure you get a labeler that meets this specific need.

Be sure to check the characteristics of the display

The

type of display on the labeler is primarily a consideration for portable labelers, as it is for desktop models. LCD or graphic displays help to provide a visual overview of how your label will look once printed.

There are different label thicknesses

While

you can settle for a basic size, many labelers can print labels of varying thickness for added durability

.

Choose a model that runs on a rechargeable battery

For

portable labelers, the power source should be an important consideration. For example, a rechargeable battery is preferable to one that uses AAA or AA batteries that will need to be replaced regularly.

The variety of fonts is important

Do you

like to get creative? Opt for a label maker that offers multiple styles (bold, italic, underline, etc.), a symbol board and font change functionality.

The best labeller depends on your needs and budget. Read our buying guide for the best products available.

Versatile and reliable, labeling machines can be used to create labels for anything you need to get and stay organized at home or in the office. Some common uses for labeling include food containers, kitchen cabinets, files and folders, tool boxes, cables and wires, school supplies, and more.

The print speed of a labeller is quoted in IPM or images per minute. This may not be important for occasional home use, but for regular business use, you won't want a slow machine if you're printing large quantities of labels.

The materials used in many laminators often contain chemicals that can affect the printing of thermal labels. These chemicals can discolor the print. Labels should not come into contact with materials made of PVC film and vinyl-containing plasticizers.

Due to the nature of printing on rolls of labels, the edges of your design may be cut off from the label. When designing, make sure that all essential parts of your design are within the dotted grey lines that appear on the label maker's display screen.

Every month we help more than 1 000 000 people buy better and smarter.

Copyright © 2022 - Made with ♥ by buyingbetter.co.uk

Your reviews and buying guides 0% advertising, 100% independent!