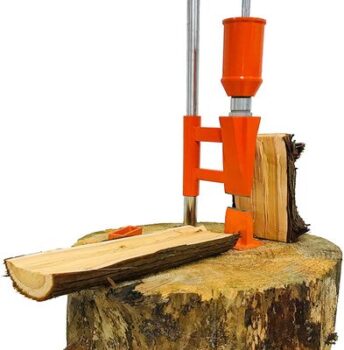

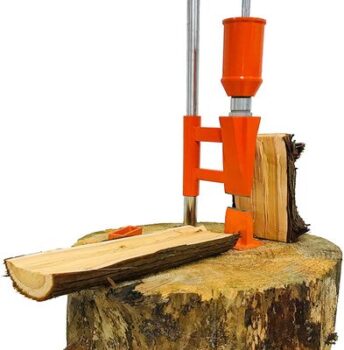

If you have access to fallen trees or cut logs, you can create your own perfectly sized firewood with a log splitter. These devices, which are available in models. These devices, which are available in manual, gas-powered or electric models, can quickly cut logs into manageable pieces of firewood. Read our guide to find the best log splitters available on the market.

Here is our commitment, to make sure that we provide the best user experience and content quality:

You can support us by using our links to make your purchases (at no extra cost to you)! This sometimes earns us a commission which allows us to remain independent. More about us

Our selection

"The LS2-7T52S hydraulic log splitter cuts horizontally. Its 2200 W motor has a force of 7 T and cuts up to 52 cm long and…"

"The Forest Master intelligent log splitter is practical and functional, powerful and efficient. With a power of 14 T it cuts up to 55 cm."

"The Zipper ZI-HS30EZ Vertical Log Splitter has a 5.5Kw motor and makes a 110 x 40 cm cut with a splitting speed of 12.5 cm/s."

"The Forest Masteur FM5T / 12 inch electric hydraulic log splitter has a 2200W motor and 5T of power, simple and easy to use."

The LS2-7T52S hydraulic log splitter cuts horizontally. Its 2200 W motor has a force of 7 T and cuts up to 52 cm long and 25 cm in diameter.

391 £ on Manomano

The Forest Master intelligent log splitter is practical and functional, powerful and efficient. With a power of 14 T it cuts up to 55 cm.

280 £ on Amazon

The Zipper ZI-HS30EZ Vertical Log Splitter has a 5.5Kw motor and makes a 110 x 40 cm cut with a splitting speed of 12.5 cm/s.

2 874 £ on Amazon

The Forest Masteur FM5T / 12 inch electric hydraulic log splitter has a 2200W motor and 5T of power, simple and easy to use.

384 £ on AmazonAny specific needs?

Your guide :

Rate this buying guide :By rating this buying guide, you are helping us to reward our best writers. Thank you!

| The TOP | The cheapest | High end | Right price/quality ratio | |

In accordance with our commitment, this buying guide does not contain any sponsored products. |

7/10 |

7/10 |

9/10 |

7/10 |

| OUR SELECTION |

EBERTH - Fendeur de bûches hydraulique LS2-7T52S

|

FOREST MASTER – Fendeur de bûches intelligent

|

ZIPPER – Fendeur de bûches vertical ZI-HS30EZ

|

FOREST MASTER – Fendeur de bûches électrique hydraulique FM5T / 12 pouces

|

|

The LS2-7T52S hydraulic log splitter cuts horizontally. Its 2200 W motor has a force of 7 T and cuts up to 52 cm long and 25 cm in diameter.

|

The Forest Master intelligent log splitter is practical and functional, powerful and efficient. With a power of 14 T it cuts up to 55 cm.

|

The Zipper ZI-HS30EZ Vertical Log Splitter has a 5.5Kw motor and makes a 110 x 40 cm cut with a splitting speed of 12.5 cm/s.

|

The Forest Masteur FM5T / 12 inch electric hydraulic log splitter has a 2200W motor and 5T of power, simple and easy to use.

|

|

|

Engine

|

2200 W

|

|

5.5 kW

|

2200 W

|

|

Power

|

7 Tons

|

14 Tons

|

30 Tons

|

5 Tons

|

|

Specifications

|

cutting dimensions up to 52cm long and 25cm diam

|

Thick slot up to 55 cm - Drill hole 2 cm - Drill depth 12 cm

|

10cm long 40cm diam. - slit speed 12.5cm/s

|

9 second cycle

|

Help us improve this table:

Report an error, request the addition of a feature to the table, or suggest another product. Thank you for your kindness!

We spend thousands of hours each year studying the major specialized websites, analyzing products of hundreds of brands and reading user feedback to advise you on the best products.

We are a product review company with a single mission: to simplify your buying decisions. Our research and testing helps millions of people every year find the best products for their personal needs and budget.

To support us you can: use our links to make your purchases (which often earns us a small commission), share our articles on social networks, or recommend our site on your blog. Thanks in advance for your support!

The power provided by a log splitter depends on its engine type. The dimensions, i.e. the length and diameter of the logs to be cut, determine the power required by the machine. The power is measured in tons and refers to the force provided by the venom on the log to cut it. The power ranges from 4 to 35 tons, depending on the model.

The splitting wedge refers to the blade of the splitter, allowing the log to be cut. There is the cross wedge. It is used to break the log into 4 pieces, allowing you to save more time. There is also the spreader wedge. As its name suggests, it spreads the wood more quickly. With this type of wedge, there is no risk of the wood getting stuck on the axe. It is especially suitable for larger and longer logs.

The mechanical wedge splits the wood lengthwise. It will then sink into the wood in order to cut it, either in 2 if it is a spreader wedge, or in 4 for a cross wedge.

There are different sources of power for a log splitter. It can be electric power, fuel, water, or even manual.

A log splitter that runs on electricity has the advantage of being less polluting and less noisy. However, its location will be reduced. Since it has to be connected to an electric cable, you will have to be placed next to an outlet. Moreover, it is less powerful. It is therefore ideal for moderate work.

There is also the log splitter that runs on fuel. It is more autonomous and more powerful. However, in addition to being cumbersome, noisy and more polluting, its consumption is also higher.

The hydraulic log splitter requires the use of a tractor if it is manual. It is equipped with a hydraulic pump and a cylinder. It is activated by a dial associated with the tractor's power take-off.

It must be said that woodworking is not the easiest, as it requires both strength and precision. In addition, some types of logs are harder of core, such as walnut, oak as well as cherry can really give you a hard time during manual splitting. Whether it's with an axe followed by a hammer, your task is going to be pretty tough, even for lumberjacks who are already professionally trained.

If only for this reason of well being, you should opt for a fashionable log splitter. The use of this new technology will both make it easier for you to transport, as most come with wheels, not to mention that almost all models come with log beds.

Despite the fact that it's not exactly cheap in terms of price, log splitters still promise you good satisfaction while avoiding the aches and pains sometimes caused when using axes or any other such equipment. Depending on the model and the brand, prices can vary enormously. However, you can count on average :

- 75 € for a manual log splitter

- 700 € for the electric model 8 tons

- 2000 € for the thermal model

These prices are however just an indication. They can go higher or lower, depending on the technical specifications and latest innovations of the equipment.

It is advisable to check the engine oil before each use of the log splitter in order to increase its service life and ensure its maintenance. In addition, it helps to maintain its power and obtain satisfactory results. Monitoring the hydraulic oil and engine oil of your log splitter will ensure the maintenance and power of your tool.

To do this:

1) Check the engine oil: remove the dipstick and clean it with a rag, then insert it again. Take it out again and check the marking, then add oil if necessary. To do this, remove the oil filler cap and refill the oil. The tank should be 75% full. If the oil needs to be changed, place a receptacle under the drain plug; remove the dipstick and plug and let the oil out. Once the tank is empty, add new oil, making sure that, as previously stated, it is 75% full. After these steps (whether you are replacing the oil or just adding more). You can then proceed to bleed the cylinder.

2) Clean the cylinder: To ensure that your device works perfectly, it is important to purge the cylinder. Indeed, an excess of air can be present in the cylinder, which reduces the power of the splitter. To do this, you need to fully extend the piston rod and remove the oil cap. Loosen the screw quickly so that the air can be released from the oil fill hole. You can then put the connector back on.

3) Change the oil filter: the filter pumps the oil from the separator. It must be changed regularly. You will just have to remove it, add some lubricant on the device and install the new filter then tighten it.

The manual log splitters are operated by applying pressure from the top to the bottom on an iron bar. It is effective only for small logs, and is quite simple to use: it includes a system to hold the wood, a wedge and a weight that provides the force needed to split the log.

Electric log splitters are operated by an electric motor connected to a mains supply. They are used on logs ranging from 60 to 100cm high and from 25 to 3 cm in diameter and for a maximum need of 12 steres per year. Its shoe can be single or double, to split the logs in 2 or 4 pieces.

They can be used for domestic use, with a pressure force of 8 to 10 tons and a power of 1500 W to 3500 W. They are most effective on small pieces of wood, which are even softer and do not have hard-to-split cores. The advantages of electric splitters are that they are quiet, easy to start and move, and less polluting. However, it must be used next to an electrical outlet.

Thermal log splitters are mostly designed for professional or semi-professional use, for larger wood needs (more than 12 steres per year); used for larger jobs, which have the task of processing larger and harder logs, while also being more resistant. Its pressure force can go up to 35 tons. They are gasoline or diesel powered and have the advantage of being particularly autonomous and powerful.

The tool is equipped with an engine that is fixed with silent rubber shock absorbers (silentblocs) with a power of 9000 W. They are usually placed on a trailer to facilitate their movement, or equipped with large wheels that can be moved with handles. They have the disadvantage of being quite noisy, but still allow cuts of 1 m or more.

Hydraulic log splitters have a pressure force from 11 tons and up to 20 tons, depending on the model. They are towed by a tractor or a mini excavator. They are also generally used for professional purposes and can be thermal. Hydraulic splitters are the most powerful and are therefore intended for more massive use. They make a split from 35 cm on average and ensure a flow of more than 12 steres per year.

Between the log splitter and the merlin splitter, the result is identical. Both are tools that break wood. Both being manual tools, it should be noted that they require physical strength. Each has its advantages and disadvantages. Through this comparison, you will be able to have a more oriented choice.

The manual splitter is an alternative to the merlin, axe or wedge. It is perfect for breaking a not too large quantity of dry wood, ideally 30cm in diameter maximum and 50cm in length maximum. The manual splitter is fairly easy to use and does not require much physical effort if the wood is dry. Moreover, it is far less dangerous than other tools for splitting or cutting wood. It is quite classic. It has a handle with a wedge on the end and a sliding part with a small hammer. Once the wedge is in the log, you just have to activate the sliding part from the top to the bottom. The small sledgehammer will split the log.

Unfortunately, for larger wood and large quantities, the manual splitter is less efficient.

The merlin is the perfect manual splitter. It was especially designed for breaking wood. With good control, the merlin is absolutely efficient. Similar to the axe, it combines two tools on one piece of equipment: the sledgehammer and the axe. The sledgehammer part is used to hit the wood and strike the corners effectively, while the axe part breaks it up. The splitting merlin weighs between 2.5 kg and 4 kg on average, depending on the size of the log to be split. Being about 90 cm long, you will have enough handle to hold and provide more striking power. The best handles are those made of composite material: flexible and robust at the same time. Wooden shafts require some skill to use, as they can break if not used properly. The short-headed merlin is the best choice, as it protects against shocks and the handle cannot be torn off.

The use of a merlin splitter requires arm strength and experience to avoid any risk of accident. If the quantity of parts to be cut is quite large, the merlin is quite tiring. However, its price remains affordable and accessible.

Between the manual splitter and the merlin splitter, the choice seems difficult because both seem to bring the same result and both have their advantages and disadvantages.

Splitting logs in accordance with standards

There are a few rules to follow if you want to get the job done safely, even if the machine is simple to use. Make sure the machine is stable and split the logs in the direction of the grain, not across it. The wood to be split should be really dry and make sure it has no knots, as this can make your work more difficult. Otherwise, always put the knots at the top to prevent them from twisting. If this persists, always keep a small sledgehammer handy to loosen the knot when jamming the log. If the concern is not that the log is stuck and not split, it is recommended to turn it on itself, so as to obtain 90 °, and take advantage of it to split it under another position.

Ensuring your safety

Splitting logs is not harmless and does not remain without risk, even when using a device that respects the standards. It starts with your hands. It is recommended to wear handling gloves, because the work is not the easiest especially for professionals. Goggles are not to be neglected either, because "slivers" can injure you when the wood breaks. A helmet against noise is also necessary when using a thermal splitter. And finally, equip yourself with shoes with reinforced toes, in case pieces of logs fall on your feet.

Installation and maintenance of the machine

As you may already know, you need to use a flat surface to install the log splitter. This should be both stable and solid. Once the log is installed in the center of the table, it should be pressed against the claws.

Always make sure that the cutting edge of the shoe of an electric log splitter is always even and clean. Also, check the air vent above the electric motor, as it can become clogged with chips. If this is the case, the motor may overheat. For the hydraulic system, the oil level should be checked regularly and changed after about 100 hours of use. And finally, you should always make sure to use unleaded gasoline, less than 30 days old for thermal models. But for diesel, it can last a little longer.

Keep the performance of the hydraulic log splitter

In order to increase the life of your hydraulic log splitter, it is important to maintain its maintenance on a regular basis. Knowing that each splitter operates differently, pay close attention to the instruction manual first and foremost. The hydraulic lines ensure the flow of fluid from the tank to the ram. Make sure they are not leaking, otherwise they should be replaced. Change the fluid once a year to maintain the performance of your unit and make sure the oil level is at ¾. Take the opportunity to also check the carburetor if the log splitter has a gasoline engine. Make sure the cylinder is always oiled and not rusted.

To remove rust from the unit

Rust installed on your splitter can deteriorate your device. It is very important to avoid its presence. A few everyday items can help get rid of it. White vinegar works on rust effectively. Soak your tool in a bowl of white vinegar overnight. You can then rinse it with water and let it dry. It is also possible to rub the rusty parts with onion cut in half with powdered sugar spread on its surface. Alternatively, rub the rusty areas of your appliance with the rough part of a sponge dipped in Coke. A baking soda paste left on the rust for half an hour is also effective. You can then scrub it with a brush.

The force of a splitter is between 4 and 30 T. It depends on the quantity of wood to be split, but a force of 7 to 10 T is perfect for a volume of up to 12 steres. For a quantity of more than 12 steres, it is better to opt for a more powerful machine.

Since each splitter has its own power, the length of the logs to be cut and the quantity must be determined. To facilitate the work of the loggers, the height of the table must also be monitored. To avoid all kinds of injuries, be sure to set the splitting option to vertical or horizontal.

Another factor you should never overlook is its strength. The more powerful the splitter is, the more wood you will get, but the work will also be done very quickly.

First, the wheels on your splitter can keep the logs stacked and make the job easier. Then, you can apply full force to a log without the wedge or hydraulic cylinder moving thanks to its durable steel construction. With this model, the log is prevented by the log cradles from rolling off the bed before they are securely in place. The hydraulic cylinder is loaded quickly without tipping over too much due to the multi-speed pumps. If these criteria are present, then you have made the right choice.

The log splitter with chain saw requires more maintenance than one with a circular saw. The latter does not require lubrication and is not affected by the presence of a foreign body on the wood. The circular saw is therefore better.

It depends on the type of machine you use, but normally you should be able to adjust this by moving the plate. You loosen a handle to move it and then tighten it again once you have the length you want.

Every month we help more than 1 000 000 people buy better and smarter.

Copyright © 2022 - Made with ♥ by buyingbetter.co.uk

Your reviews and buying guides 0% advertising, 100% independent!